Hi and thanks for you help.

I am running nearly the same code as you, with the exception that I have the setMode a bit further down and I haven't set extra dealy for that (might be somewhat the reason for the issues).

`

#include <Trill.h>

Trill trillSensor;

void setup() {

// put your setup code here, to run once:

Serial.begin(115200);

int ret = trillSensor.setup(Trill::TRILL_FLEX);

if(ret != 0) {

Serial.println("failed to initialise trillSensor");

Serial.print("Error code: ");

Serial.println(ret);

}

// when the slider is connected we increase the

// prescaler to deal with the increased baseline

// capacitance it brings

trillSensor.setPrescaler(4);

delay(10);

// after any prescaler change, it's always good to update

// the baseline, too.

trillSensor.updateBaseline();

trillSensor.setMode(Trill::RAW);

}

void loop() {

// put your main code here, to run repeatedly:

delay(100);

trillSensor.requestRawData();

while(trillSensor.rawDataAvailable() > 0) {

int data = trillSensor.rawDataRead();

if(data < 1000)

Serial.print(0);

if(data < 100)

Serial.print(0);

if(data < 10)

Serial.print(0);

Serial.print(data);

Serial.print(" ");

}

Serial.println("");

}

`

I have been playing around with both a lot now

What i figured out so far

*your code with the delay and mode change earlier seems to be more robust (makes sense to have it earlier)

*the rev.A2 doesn't care what so ever. both of those codes work exactly the same

*the rev.C1 does care

One example that I have now that seems to be very reproducable.

I take your code, flash it on the UNO, have the C1 connected. I get good response to the changes, everything seems to be fine (signal around 500 at prescaler(4) with the flexPCB). I can take the Trill sensor off the hub an plug it back in, all fine.

I then flash my code. Everything is the same, all good. I unplug the Trill sensor, plug it back it and i get maxed out values (or around 2700 without flexPCB). I can reset the UNO, reflash the code, no changes. The complete power cycle seems to reset something. IF I reflash it to your code, back to normal.

And that only happens on the C1, A2 is code agnostic in that example.

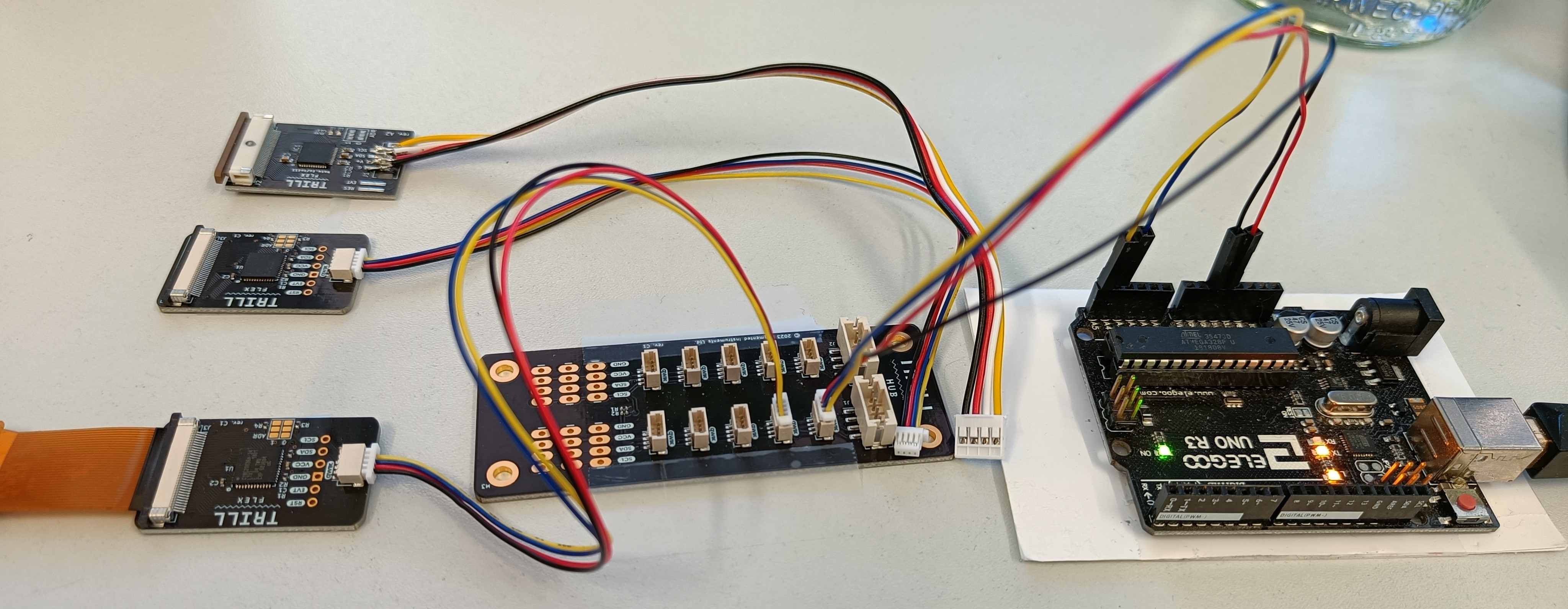

I have a photo of my test set up attached, just for reference.

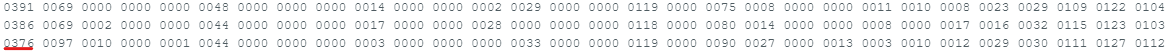

Also I might have at least one C1 that is broken, with 300-400 points higher signal on the first pin and very highly fluctuating baselines, making it not usable over the whole slider.

prescaler(4), no flexPCB:

I know I have a working solution now, but I would like to know why they behave so differently so I can avoid that in the future. But in general already thanks for you help, its very much appreciated!